Untrained Leak Detection Leads to Unnecessary Structural Damage

Date of Service: December 1, 2025

Service Type: Residential Leak Detection

Performed By: Pegasus Leak Detection

Background: When Equipment Is Mistaken for Expertise

Pegasus Leak Detection was contacted after a referring company attempted to locate a leak using an in-house employee. The result was immediate and significant damage to the customer’s home—without the leak ever being identified.

Upon arrival, it became clear that fundamental leak detection procedures were never followed. The individual who performed the initial work disclosed they had no formal leak detection training and was sent solely because they had access to basic audio equipment.

Unfortunately, this reflects a widespread issue in the industry:

many companies offer leak detection services without having trained leak detection professionals.

Pegasus was brought in to correctly identify the leak, assess the damage, and determine the proper repair path.

What Went Wrong: Critical Errors Observed On Site

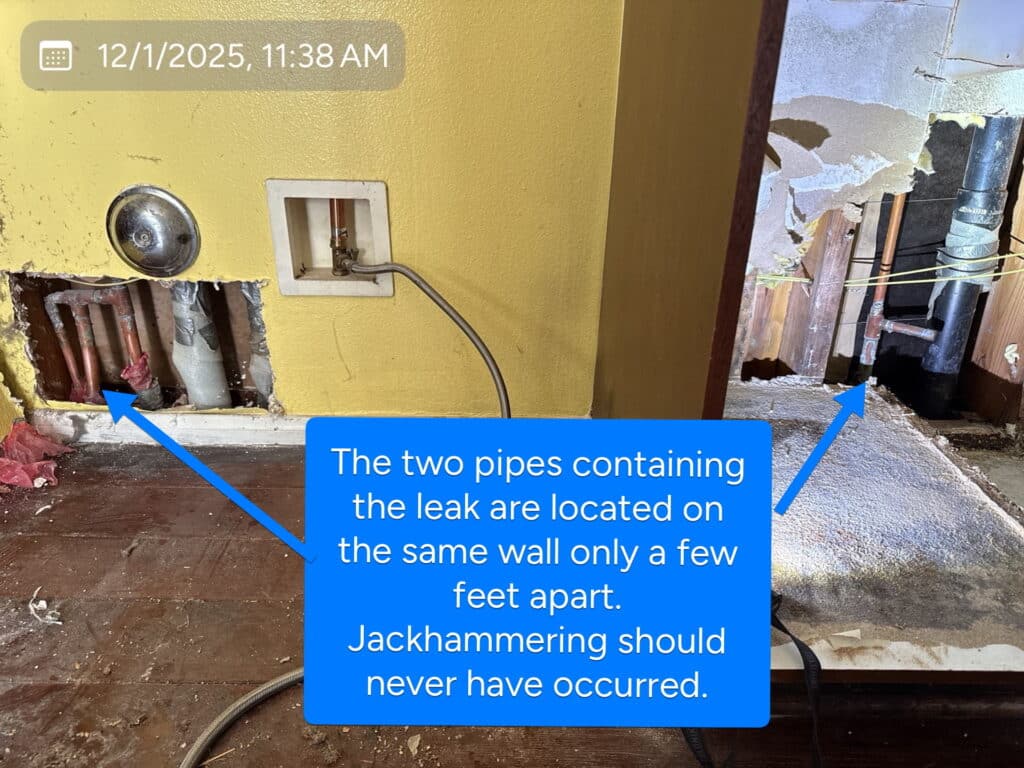

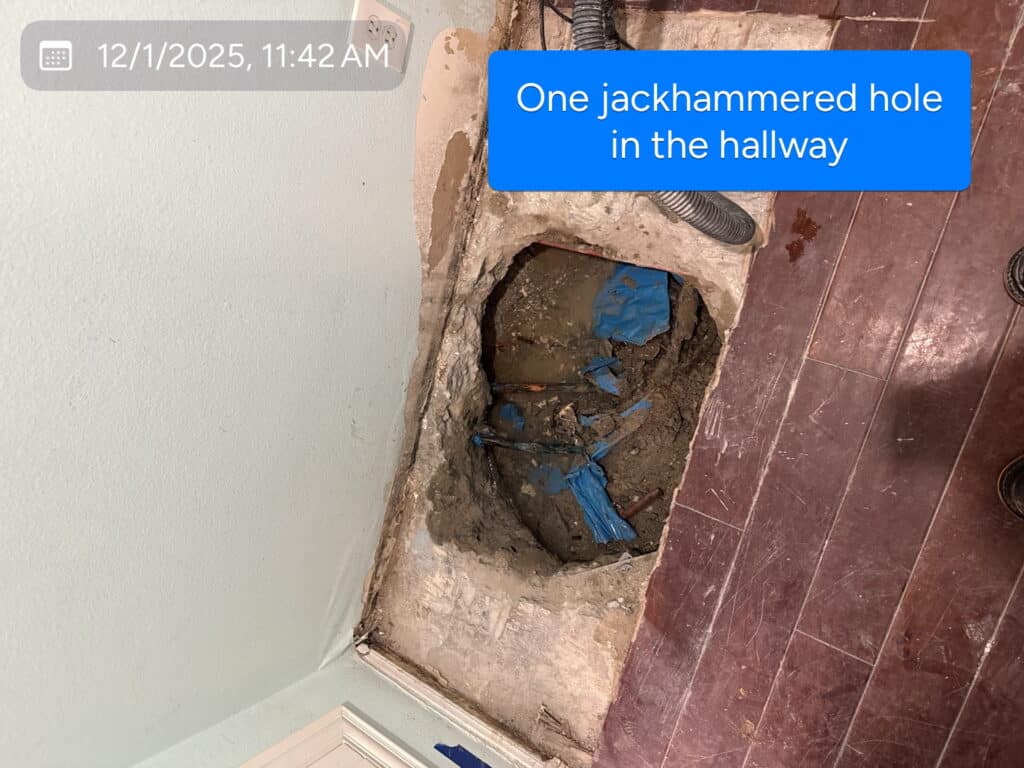

Multiple Unnecessary Jackhammered Openings

Two large holes had already been jackhammered through finished hardwood flooring and the concrete slab:

- Hole #1: Contained piping and some moisture

- Hole #2: Contained no piping and no moisture

The second opening confirmed that no proper pipe path verification or locating process was used.

Both holes were placed in areas not connected to the actual leak location.

No Utility Locating Performed

The presence of an empty slab opening is a clear indicator that utility locating was never performed.

Accurate leak detection must always begin by mapping pipe routes.

Skipping this step guarantees unnecessary destruction.

Permanent Structural Damage Created

The jackhammering breached the damp-proof membrane (DPM) beneath the slab.

This membrane is required by building code to prevent subsurface moisture intrusion.

Once cut, it cannot be repaired or resealed properly.

This mistake permanently increased the property’s risk of long-term moisture intrusion.

Pegasus Leak Detection’s Investigation Process

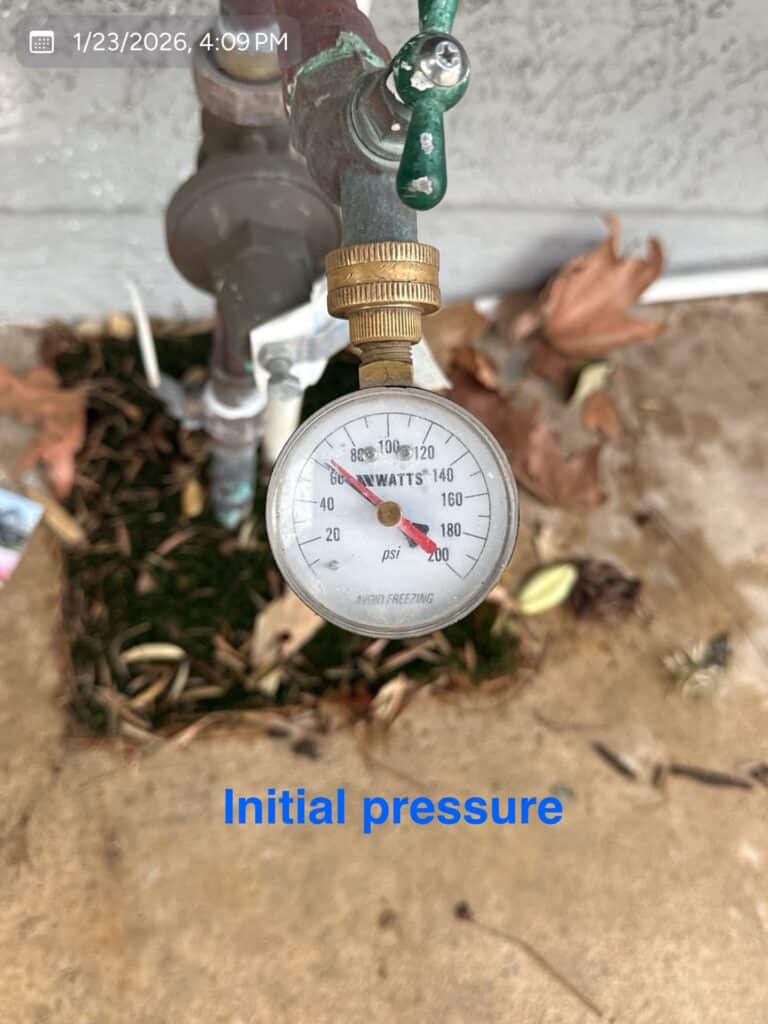

Pegasus applied its patented methodologies, precision locating technology, and structured diagnostics to identify the leak accurately and non-destructively.

Step 1: System Isolation

The leak was isolated to the hot water system, immediately narrowing the scope.

Step 2: Manifold Identification

Using advanced locating equipment, Pegasus identified an above-ground manifold located behind the refrigerator that supplied an upstairs fixture.

Step 3: Exact Pipe Identification (Patented Methodology)

Pegasus then:

- Identified the exact pipe within the manifold that was leaking

- Traced the pipe’s route accurately

- Located the precise entry and exit points through the slab

The underground pipe traveled only 3.5 feet beneath the slab.

The failure point was exactly within that short section.

The Correct Repair Path (What Should Have Happened)

Minimal-Impact Repair Plan

With the correct diagnosis, the proper repair would have been:

- Opening 3.5 feet of wall

- Installing 3.5 feet of new piping

- Bypassing the underground section entirely

This repair could have been completed in a few hours, with:

- No slab cutting

- No flooring removal

- No permanent structural damage

What Occurred Instead

The untrained technician:

- Jackhammered multiple holes through finished flooring

- Cut into the slab without locating the leak

- Breached the damp-proof membrane

- Failed to identify the leak

- Escalated a simple repair into major construction

All of this was entirely preventable.

Consequences for the Homeowner

Structural Damage

- Hardwood flooring destroyed in multiple rooms

- Concrete slab unnecessarily breached

- Damp-proof membrane permanently compromised

- Increased long-term moisture intrusion risk

Financial & Logistical Impact

The homeowner now faces:

- Flooring replacement

- Moisture mitigation

- Slab monitoring or sealing

- Additional plumbing and construction costs

- Extended repair timelines

What should have been a low-cost, same-day repair became a major project.

Why This Matters: An Industry-Wide Problem

This case highlights a serious issue in the leak detection industry.

Key Takeaways

- Leak detection is a specialized trade, not an add-on service

- Equipment alone does not equal competence

- Many companies market leak detection without the ability to perform it

- Improper detection causes unnecessary destruction and financial harm

Pegasus Leak Detection is frequently called in after damage has already occurred—often by plumbing companies who recognize the limits of their internal capabilities.

On-Site Observations of the Initial Technician

The technician responsible for the destructive work remained on site during Pegasus’ investigation. Their questions and reactions demonstrated:

- No formal leak detection training

- No familiarity with utility locators

- No understanding of manifold systems

- No process-of-elimination methodology

- No knowledge of pipe routing analysis

This lack of training directly resulted in the damage inflicted on the property.

Conclusion: Why Qualified Leak Detection Matters

This case is a clear example of how untrained leak detection practices cause permanent and unnecessary harm.

The homeowner endured:

- Avoidable structural damage

- Significant financial loss

- Permanent compromise of their concrete slab

Pegasus Leak Detection’s patented processes enabled:

- Accurate, non-destructive leak identification

- Proper mapping of underground and manifold-fed piping

- A minimal-impact repair plan

- Prevention of further damage

This incident reinforces the urgent need for training, standardization, and accountability in leak detection—to protect homeowners and ensure the work is done right the first time.