PVC and Non-Metallic Industry

PVC and Non-Metallic Leak Detection

Detecting leaks in PVC and non-metallic pipes requires specialized tools and expertise, as these materials present challenges that traditional methods cannot overcome. At Pegasus Leak Detection, we have the knowledge, equipment, and techniques to identify and address leaks in non-metallic systems, ensuring that even the most difficult leaks are detected and resolved quickly. For expert leak detection services tailored to the PVC and non-metallic industry, contact Pegasus Leak Detection today and let us help protect your infrastructure and resources.

Leak Detection in the PVC and Non-Metallic Industry

Overview

PVC and non-metallic pipes present unique challenges in the world of leak detection. While these materials are widely used in various industries due to their durability, resistance to corrosion, and cost-effectiveness, they are notoriously difficult to detect and diagnose when leaks occur. Unlike metallic pipes, PVC and other non-metallic materials do not conduct sound or support traditional locating methods, making accurate leak detection a specialized task. At Pegasus Leak Detection, we employ advanced technologies and techniques specifically designed to locate and diagnose leaks in non-metallic systems.

The Unique Challenges of PVC and Non-Metallic Pipe Leak Detection

Leak detection in PVC and non-metallic pipes is more complex than in traditional metallic systems for several reasons:

- Minimal Noise from Leaks: Unlike metallic pipes that often emit a noticeable “hissing” or “whooshing” sound when leaking, PVC pipes and other non-metallic materials tend to develop cracks or fitting issues that release water in a subtle, quiet manner. These leaks are harder to detect with traditional acoustic leak detection methods.

- Lack of Pinholes: Non-metallic pipes, especially PVC, are less likely to develop pinhole leaks. Instead, they often experience cracks, fissures, or compromised joints that mist water rather than shoot it out, resulting in a more gradual and quieter leak.

- Non-Metallic Composition: Since PVC and other non-metallic pipes do not have conductive properties, they cannot be traced using electromagnetic locators. This means that traditional pipe locating equipment is ineffective, making utility mapping and leak detection much more challenging.

Innovative Solutions for PVC and Non-Metallic Leak Detection

At Pegasus Leak Detection, we use cutting-edge tools and methods specifically designed to address the unique difficulties posed by PVC and non-metallic pipes. These advanced techniques help ensure that even the most difficult-to-detect leaks are found quickly and efficiently:ce Guidance

- Pulsed Water Column Detection: By inducing a controlled pulse within the water column, we can create a small, detectable vibration in the water inside PVC pipes. Using highly sensitive ultrasonic equipment, we can listen for the pulse along the length of the pipeline, allowing us to trace and locate leaks that would otherwise remain hidden.

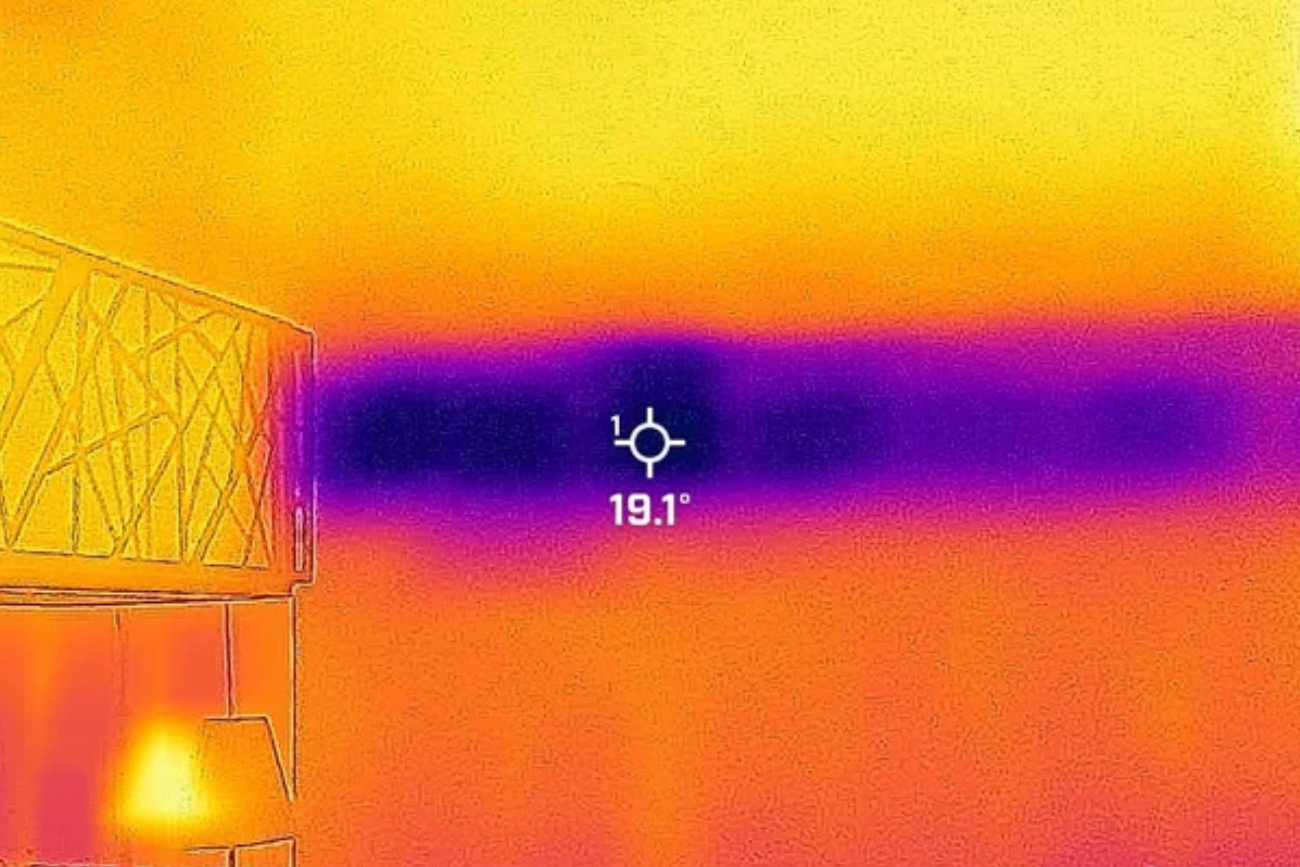

- Ultrasonic Leak Detection: Although PVC pipes do not generate much noise when leaking, our ultrasonic detection equipment can identify subtle vibrations or pulses within the water, helping us detect and trace leaks in non-metallic systems. This method is especially useful when leaks are too quiet for traditional acoustic tools.

- Traceable Rodder Insertion: For non-metallic pipes, such as PVC, that cannot be detected using conventional electromagnetic locators, we use a traceable rodder. By inserting the rodder into the pipeline, we can follow its path with specialized detection equipment, mapping out the non-metallic pipeline and identifying potential leaks or weak points.

- Tracer Gas Detection: In some cases, tracer gas can be injected into the non-metallic pipe system. The gas will escape through any cracks or compromised joints, and our detection equipment will identify the location of the gas, allowing us to pinpoint the leak.

Best Practices for PVC and Non-Metallic Leak Detection

Detecting leaks in PVC and non-metallic pipes requires specialized approaches. Here are the best practices to ensure success:

- Routine Inspection and Monitoring: Regularly scheduled inspections, especially in older PVC installations or areas prone to soil shifting, can help identify potential problems before they escalate into significant leaks.

- Use of Advanced Equipment: The unique properties of non-metallic pipes require specialized detection tools, such as pulsed water column detectors, traceable rods, and ultrasonic devices designed for PVC systems.

- Pinpointing Compromised Fittings: Since PVC pipes are more likely to develop issues with joints and fittings rather than along the pipe’s length, extra attention should be paid to these vulnerable areas during inspections.

- Proactive Leak Prevention: Monitor pressure and flow rates in systems using PVC or non-metallic pipes. Sudden changes in these parameters may indicate a crack or compromised joint that needs further investigation.

- Partner with Leak Detection Experts: Given the specialized nature of PVC and non-metallic pipe leak detection, it’s critical to work with an experienced team like Pegasus Leak Detection. Our expertise in advanced detection methods ensures accurate results.

The Environmental and Financial Impacts of Undetected PVC Leaks

The consequences of undetected leaks in PVC and non-metallic systems can be significant:

- Water Loss: Even small, quiet leaks in PVC pipes can result in massive water waste over time. Since these leaks often go unnoticed for extended periods, the financial costs and environmental impact can be substantial.

- Infrastructure Damage: Leaks in non-metallic systems may lead to soil erosion or subsurface water accumulation, which can damage surrounding infrastructure like roads, foundations, and nearby buildings.

- Increased Repair Costs: Delayed detection of PVC leaks often results in more expensive repairs due to the gradual buildup of water-related damage.

- Regulatory Compliance Issues: In industries where environmental conservation and water management regulations are strict, undetected leaks can lead to non-compliance, resulting in fines and legal consequences.

Regulatory Compliance in the PVC and Non-Metallic Industry

Leak detection in non-metallic systems must adhere to specific regulations and industry standards:

- Water Management Regulations: In water distribution and management sectors, regulatory bodies like the Environmental Protection Agency (EPA) mandate that systems must minimize water loss. Undetected leaks in PVC pipelines can cause non-compliance.

- Building and Safety Codes: Many local and national building codes require proper leak detection in PVC and non-metallic plumbing systems to ensure building safety and prevent water damage.

- Environmental Impact Standards: PVC and other non-metallic leaks can affect local ecosystems, especially if they go undetected. Compliance with environmental standards ensures the protection of groundwater and soil.

Get in Touch

If you have any questions or need professional leak detection services, don’t hesitate to contact me, Philip, at Pegasus Leak Detection. I am dedicated to providing reliable, efficient, and effective solutions to meet your needs.

Protect your property, conserve resources, and reduce your environmental impact. Reach out now for expert leak detection services.