Leak Detection in the Gas Industry

Gas Industry

Leak detection is a critical component of the gas industry, helping companies manage risk, maintain compliance, and protect the environment. With advanced detection technologies and a proactive approach, gas companies can identify and repair leaks before they escalate into major issues. For expert leak detection services tailored to the gas industry’s needs, contact Pegasus Leak Detection today. Let us help you safeguard your infrastructure, protect the environment, and ensure regulatory compliance.

Leak Detection in the Gas Industry

Overview

The gas industry is highly regulated due to the potential dangers and environmental impacts associated with gas leaks. Gas leak detection is crucial for ensuring safety, maintaining regulatory compliance, and minimizing economic losses. Leaks in gas pipelines or storage facilities can lead to hazardous conditions, including explosions, fires, and harmful emissions. Leak detection systems play an essential role in preventing these risks while improving the efficiency of gas distribution networks.

The Importance of Gas Leak Detection

Gas leak detection is vital for numerous reasons, including:

- Safety: Gas leaks pose a serious threat to public health and safety. Methane and other gases are highly flammable and can cause explosions if not addressed promptly.

- Environmental Impact: Methane, the primary component of natural gas, is a potent greenhouse gas. Undetected leaks contribute to increased atmospheric methane levels, accelerating climate change.

- Compliance with Regulations: The gas industry is subject to strict safety and environmental regulations. Proactively detecting and repairing leaks helps companies avoid penalties and fines while ensuring compliance.

- Operational Efficiency: Leaks can result in significant losses for gas companies. Detecting and repairing leaks early saves money by minimizing product loss and reducing the cost of repairs.

- Public Trust: Gas companies are entrusted with maintaining safe and reliable infrastructure. Ensuring prompt leak detection and repair maintains public confidence and operational integrity.

Common Leak Sources in the Gas Industry

Leaks in the gas industry can occur in a variety of places, from distribution networks to storage systems. Some common sources of gas leaks include:

- Underground Pipelines: Corrosion, aging infrastructure, and external damage can cause leaks in underground gas lines, which are often difficult to detect without specialized equipment.

- Above-Ground Storage Facilities: Gas storage tanks and facilities are vulnerable to leaks due to corrosion, equipment failure, and wear over time.

- Distribution Networks: Leaks in gas distribution systems, especially at joints, valves, and fittings, can result in lost product and safety hazards.

- Appliance Connections: Improper connections between gas pipelines and appliances can lead to slow, undetected leaks in commercial and residential settings.

- Compressor Stations and Valves: Over time, wear and tear on valves and compressor stations can lead to leaks, requiring routine inspections.

Advanced Leak Detection Technologies

The gas industry relies on a variety of advanced technologies to detect leaks quickly and accurately:

- Ultrasonic Leak Detection: This technique uses sound waves to detect gas leaks by picking up high-frequency sounds emitted by gas escaping under pressure.

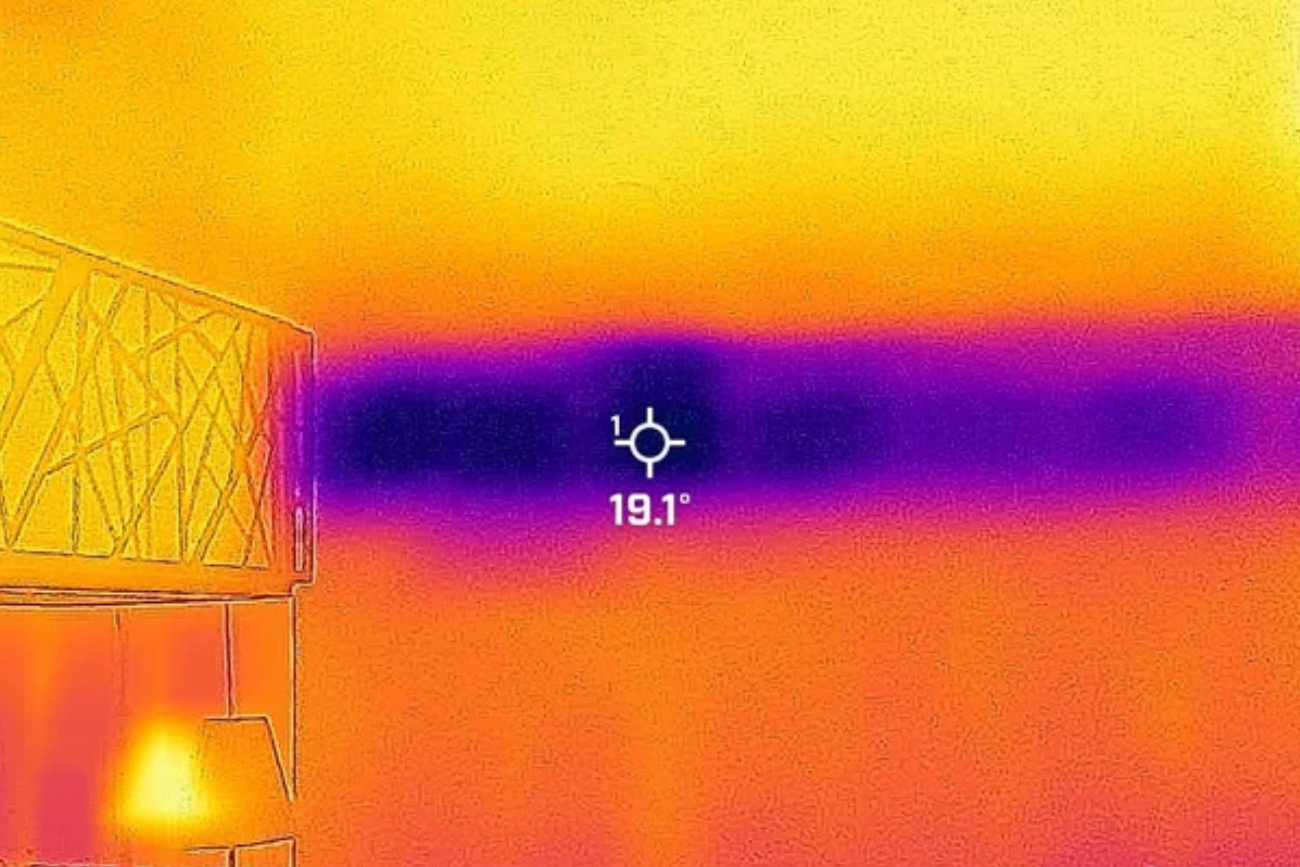

- Infrared Imaging: Infrared cameras detect gas leaks by visualizing heat signatures and differences in gas concentrations. This non-invasive technique is particularly useful for monitoring pipelines and large storage facilities.

- Tracer Gas Detection: Tracer gas is injected into pipelines, and when it escapes through a leak, specialized sensors detect its presence, pinpointing the exact location of the leak.

- Optical Gas Imaging (OGI): OGI cameras are designed to detect gases invisible to the naked eye, including methane. These cameras are highly effective for identifying gas leaks at refineries, processing plants, and pipelines.

- Continuous Monitoring Systems: Some gas networks use real-time monitoring systems that detect changes in pressure, flow, and gas concentrations, triggering alerts when anomalies indicative of leaks are detected.

Best Practices for Gas Leak Detection

To ensure efficient and reliable leak detection, the gas industry follows several best practices:

- Routine Inspections: Regular inspections of pipelines, storage tanks, and facilities are critical for identifying potential issues before they lead to leaks.

- Use of Redundant Technologies: Combining multiple leak detection methods, such as acoustic sensors and infrared imaging, improves the likelihood of detecting leaks early.

- Training Personnel: Proper training in leak detection technologies and methods ensures that employees can quickly identify and respond to potential leaks.

- Partnering with Specialists: Engaging with expert leak detection companies, like Pegasus Leak Detection, provides access to cutting-edge technology and expert knowledge, enabling rapid identification and repair of gas leaks.

- Real-Time Monitoring: Installing real-time monitoring systems helps companies detect gas leaks as soon as they occur, reducing response time and preventing larger issues.

Environmental and Financial Impact

The environmental and financial consequences of undetected gas leaks are significant:

- Greenhouse Gas Emissions: Methane leaks contribute heavily to greenhouse gas emissions, exacerbating climate change. Addressing leaks promptly is essential for reducing the industry’s carbon footprint.

- Cost Savings: By preventing product loss and avoiding regulatory fines, effective leak detection saves gas companies significant money.

- Community Health and Safety: Detecting gas leaks quickly protects the health and safety of nearby communities, preventing accidents, fires, and long-term exposure to harmful gases.

Regulatory Compliance in the Gas Industry

Gas companies must comply with strict safety and environmental regulations, such as:

- PHMSA Regulations: The U.S. Pipeline and Hazardous Materials Safety Administration (PHMSA) requires regular inspections and the use of leak detection technologies to maintain the integrity of gas pipelines.

- EPA Emissions Guidelines: The Environmental Protection Agency (EPA) mandates limits on methane emissions and requires gas companies to actively monitor and repair leaks in their infrastructure.

- International Standards: Global standards, such as the International Gas Union (IGU) and the International Organization for Standardization (ISO), also place emphasis on leak detection as part of their safety and environmental protocols.

Get in Touch

If you have any questions or need professional leak detection services, don’t hesitate to contact me, Philip, at Pegasus Leak Detection. I am dedicated to providing reliable, efficient, and effective solutions to meet your needs.

Protect your property, conserve resources, and reduce your environmental impact. Reach out now for expert leak detection services.