Leak Detection in the Energy Industry

Energy Industry

Effective leak detection in the energy industry is key to maintaining operational efficiency, ensuring safety, and reducing environmental impact. By leveraging advanced technologies and following best practices, energy companies can detect leaks early, minimize energy loss, and ensure compliance with regulatory standards. For expert leak detection services tailored to the needs of the energy industry, contact Pegasus Leak Detection today. We’re here to help you protect your infrastructure, maximize efficiency, and minimize risks.

Leak Detection in the Energy Industry

Overview

In the energy industry, leak detection is essential for maintaining operational efficiency, ensuring safety, and reducing environmental impact. Leaks in energy systems, whether related to gas, oil, air, or cooling systems, can lead to significant energy loss, financial waste, and potentially hazardous conditions. From power plants to renewable energy facilities, leak detection is a critical component of maintaining a safe and efficient energy infrastructure.

The Importance of Leak Detection in the Energy Industry

Leak detection in the energy sector is crucial for several reasons:

- Operational Efficiency: Leaks result in lost energy, increased production costs, and reduced system efficiency. Early detection helps minimize these losses and improves overall performance.

- Safety and Risk Mitigation: Leaks in energy systems—particularly those involving gas, steam, or compressed air—can pose significant safety risks. Detecting and addressing leaks early prevents accidents, fires, and hazardous emissions.

- Regulatory Compliance: The energy industry is subject to strict regulations regarding emissions, safety, and energy efficiency. Effective leak detection helps companies meet regulatory requirements and avoid fines or legal consequences.

- Environmental Protection: Leaks in oil, gas, or chemical systems can lead to environmental contamination, affecting air quality and ecosystems. Proactive leak detection minimizes the environmental footprint of energy operations.

- Cost Savings: Energy leaks contribute to substantial financial losses due to wasted resources. Detecting and repairing leaks reduces waste, leading to cost savings in production and distribution.

Common Leak Sources in the Energy Industry

Leaks can occur in a variety of energy systems, including:

- Steam and Heat Systems: Leaks in steam systems cause energy loss, reduced efficiency, and pressure imbalances, leading to higher operational costs.

- Compressed Air Systems: Compressed air leaks are common in industrial plants and can waste significant amounts of energy if undetected.

- Gas Turbines and Boilers: Leaks in gas turbines, boilers, and other high-pressure systems can result in performance losses and pose serious safety risks.

- Oil and Gas Pipelines: Corrosion, mechanical failure, or environmental factors can lead to undetected leaks in pipelines, resulting in financial loss and environmental damage.

- Renewable Energy Systems: In solar, wind, and hydroelectric systems, leaks in cooling, lubrication, or energy storage systems can reduce efficiency and lead to maintenance issues.

Advanced Leak Detection Technologies

The energy industry relies on a variety of advanced technologies to identify leaks quickly and accurately, helping to minimize downtime and improve safety:

- Ultrasonic Leak Detectors: Used to identify leaks in pressurized systems such as steam, gas, and compressed air systems by detecting high-frequency sounds generated by escaping fluids or gases.

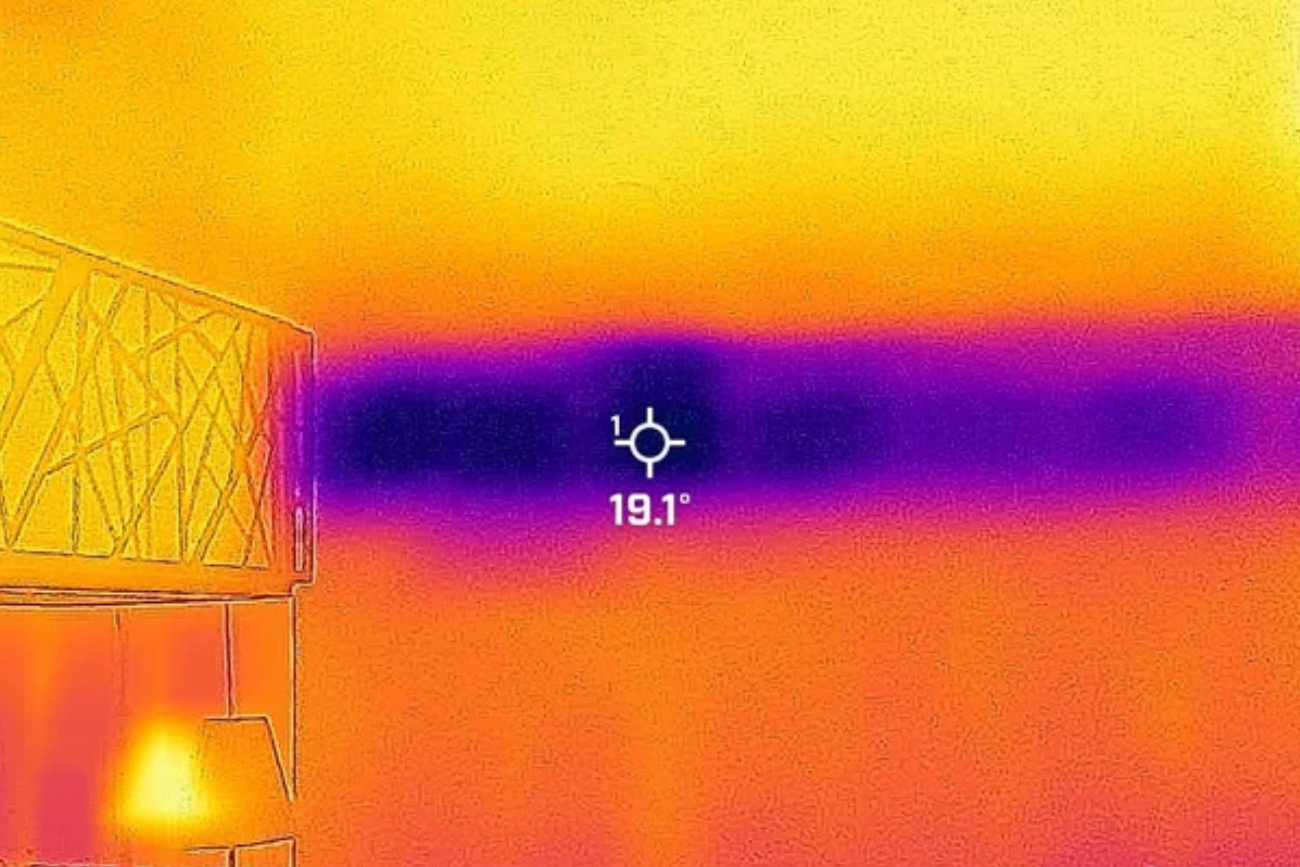

- Infrared Thermography: Infrared cameras detect temperature variations in equipment and pipelines, helping to identify leaks or inefficiencies in thermal energy systems.

- Tracer Gas Testing: Tracer gas is injected into pressurized systems to detect leaks. This method is particularly effective in gas and air leak detection.

- Acoustic Sensors: These sensors detect the sound of gas, steam, or liquid escaping under pressure, enabling precise localization of leaks in pipelines and other energy systems.

- Continuous Monitoring Systems: Real-time monitoring of energy systems using pressure, flow, and temperature sensors can alert operators to potential leaks before they become significant problems.

Best Practices for Leak Detection in the Energy Industry

To ensure optimal leak detection and maintain the efficiency of energy systems, companies should adopt the following best practices:

- Regular Inspections: Conduct routine inspections of energy systems to identify potential issues before they lead to major leaks.

- Implement Redundant Detection Methods: Use a combination of detection technologies (e.g., ultrasonic, infrared, and acoustic) for more accurate results.

- Training and Safety Protocols: Ensure personnel are trained to recognize early signs of leaks and respond promptly. Establish clear protocols for addressing leaks to reduce downtime and maintain safety.

- Real-Time Monitoring: Implementing continuous monitoring systems allows for immediate detection of anomalies, minimizing energy waste and preventing potential hazards.

- Engage Leak Detection Experts: Partnering with specialized leak detection companies like Pegasus Leak Detection ensures you have access to cutting-edge technology and expertise to handle even the most complex energy systems.

Environmental and Financial Impacts

Leaks in energy systems not only pose a risk to operational efficiency but also have serious financial and environmental implications:

- Energy Loss: Leaks in steam, gas, and air systems can waste substantial amounts of energy, leading to increased production costs and reduced profitability.

- Increased Emissions: Leaks in gas and oil systems can lead to higher emissions of greenhouse gases, contributing to climate change and violating environmental regulations.

- Cost of Downtime: Leaks in critical energy infrastructure can result in unscheduled maintenance and downtime, leading to significant financial losses for energy producers and distributors.

- Environmental Contamination: Leaks in oil pipelines or energy storage systems can result in spills that cause environmental harm, affecting ecosystems and public health.

Regulatory Compliance in the Energy Sector

Leak detection is essential for maintaining compliance with the numerous regulations governing the energy sector. Key regulations include:

- Environmental Protection Agency (EPA) Standards: The EPA sets limits on emissions and energy waste, making leak detection critical for avoiding fines and penalties.

- Occupational Safety and Health Administration (OSHA) Requirements: OSHA mandates the safe operation of energy systems, including proper leak detection and response protocols.

- International Energy Regulations: The energy industry must adhere to global standards such as the International Energy Agency (IEA) guidelines, ensuring sustainable and safe energy production.

Get in Touch

If you have any questions or need professional leak detection services, don’t hesitate to contact me, Philip, at Pegasus Leak Detection. I am dedicated to providing reliable, efficient, and effective solutions to meet your needs.

Protect your property, conserve resources, and reduce your environmental impact. Reach out now for expert leak detection services.