Complex Irrigation Leak on a Large, Non-Traditional Property

Date of Service: December 4, 2025

Service Type: Irrigation Leak Detection

Performed By: Pegasus Leak Detection

Overview: When Irrigation Layouts Defy Assumptions

On December 4, 2025, a homeowner reported continuous water flow on their water meter, even though all fixtures were shut off. Pegasus Leak Detection was contracted to identify the source of an underground leak.

This was not a typical residential property.

The lot was large, irregular, and non-traditional, with an irrigation system that lacked any predictable layout. These conditions clearly demonstrate why leak detection requires specialized expertise, why plumbing companies are not equipped to handle this work, and why industry regulation is needed to protect consumers.

Property & System Challenges

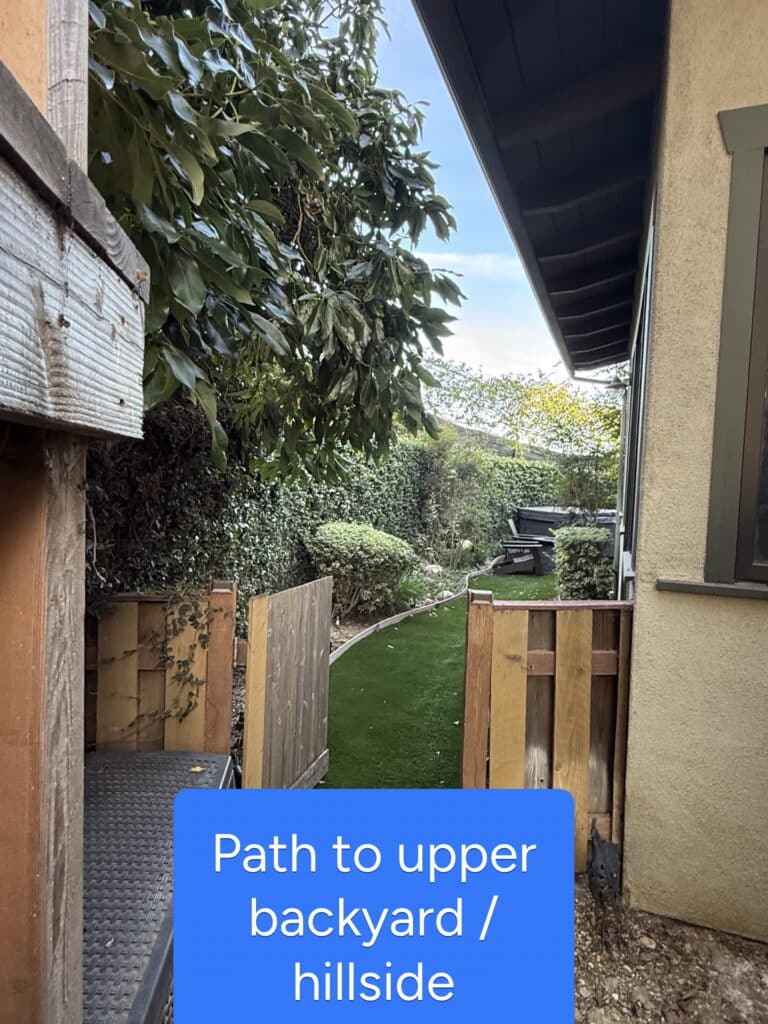

Unlike standard homes—where irrigation lines generally follow perimeter routes—this property presented significant challenges:

- Irrigation valves placed randomly across the property

- Hose bibs positioned without any clear pattern

- Pipe runs crossing mid-yard, perimeter areas, and hillside sections

- No logical or traceable irrigation layout

- Extensive use of PVC irrigation piping

Each of these factors compounds the difficulty of accurate leak detection.

Why PVC Irrigation Leaks Are Extremely Difficult to Diagnose

PVC irrigation systems present some of the most challenging conditions for leak detection.

Technical Limitations of PVC Pipe

- PVC is non-conductive, making it invisible to standard utility locators

- PVC does not transmit sound efficiently, eliminating long-range acoustic listening

- Most PVC failures involve:

- Cracked pipe

- Compromised fittings

- Joint separations

These failure modes release low-energy water escape, not high-impact acoustic noise.

As a result:

- Leak noise dissipates rapidly

- Audible signatures are only detectable at very close range

- Pipe routing is unknown and cannot be traced conventionally

In practical terms, this means you are searching for:

A leak you cannot hear, in pipe you cannot trace, within a layout you cannot predict.

This is exactly why plumber-grade tools and untrained personnel cannot perform true leak detection in these environments.

Isolation Testing: Establishing the Ground Truth

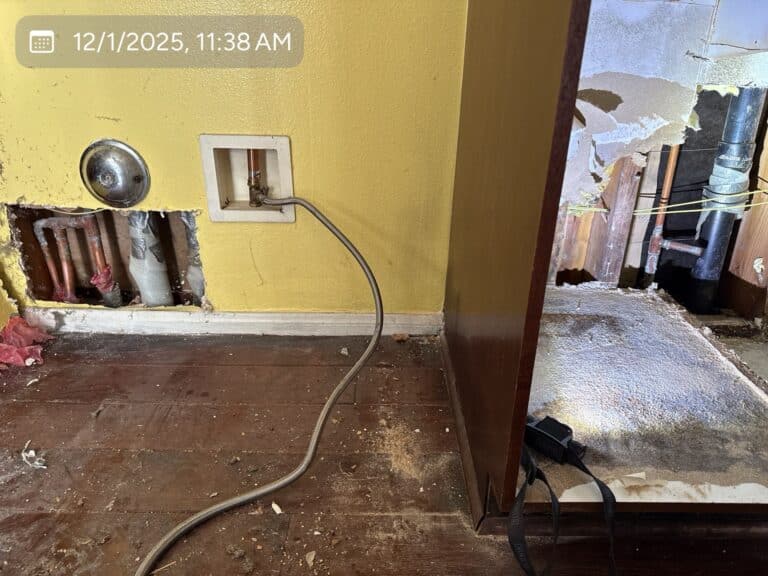

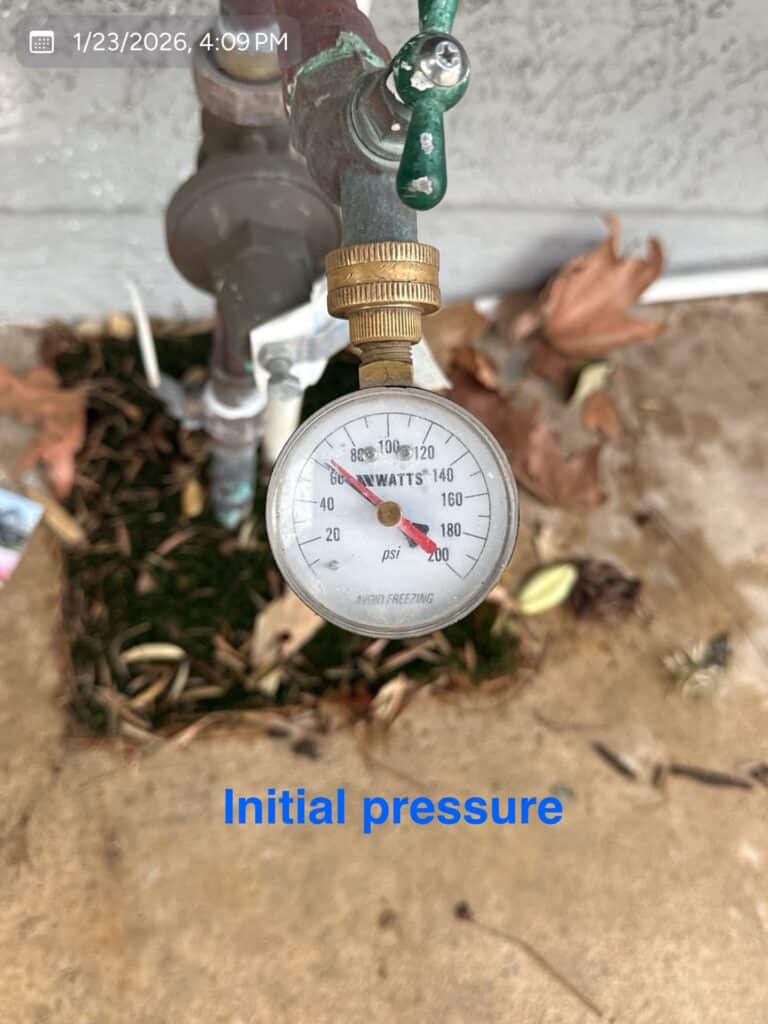

As qualified leak detection specialists, Pegasus began with the most critical step: system isolation.

Pressure Test Results

- Main house supply: Held pressure

- Interior plumbing: Held pressure

- Irrigation system: Failed pressure test

The leak was conclusively isolated to the irrigation system.

No leak noise was audible at any accessible fixtures—an expected outcome with PVC systems.

This is typically the point where unqualified providers begin guessing, digging, or escalating invasive methods. The absence of industry standards allows this behavior to occur—often at the homeowner’s expense.

Complexity Assessment: Why This Could Have Become a Multi-Day Job

Given the scale of the property and the disorganized irrigation layout, locating the leak without further segmentation could have required:

- Hours or days of exploratory searching

- Soil drilling to gain acoustic access

- Sequential tracer-gas injections with uncertain reach

- Repeated zone testing with limited direction

- No certainty that the correct area was even being investigated

Compounding variables included:

- Tracer gas may never reach the leak

- Gas may reach the leak but never surface

- PVC failures may generate no detectable noise

- Pipe routing was completely unknown

- PVC cannot be located with standard equipment

Handled improperly, this type of job exposes homeowners to significant cost and unnecessary disruption.

Pegasus Leak Detection’s Diagnostic Strategy

Despite the unpredictability of the system, Pegasus applied structured methodology and specialized tools to minimize uncertainty.

Rhythmic Pulse + Ultrasonic Detection

This approach:

- Sends a controlled pulse through the water column

- Allows ultrasonic receivers to detect relative pipe routing

- Helps approximate pipe direction and location

- Reduces blind searching

However, rhythmic pulse methods lose effectiveness in dense, chaotic pipe networks—exactly what existed on this property.

Under normal circumstances, this case could have required multiple extended visits.

The Breakthrough: Pre-Existing Isolation Valves

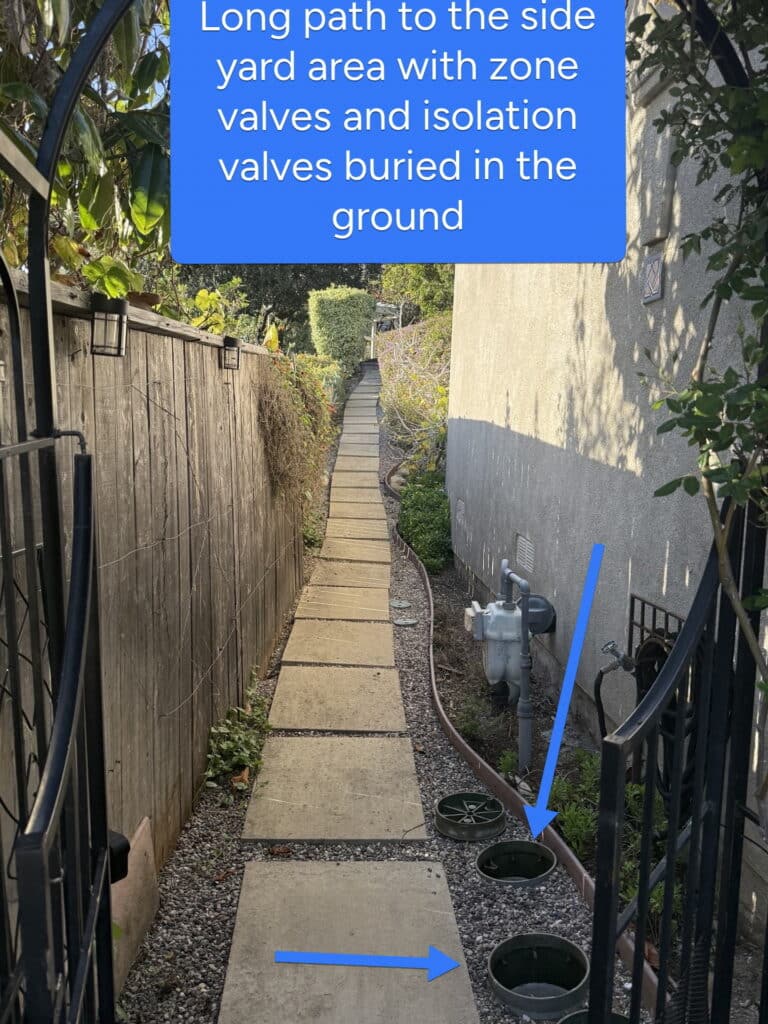

During inspection, Pegasus discovered the homeowner had multiple isolation valves already installed throughout the irrigation system.

This changed everything.

System Segmentation: Turning Chaos into Clarity

Using the existing isolation valves, Pegasus was able to:

- Divide the irrigation network into logical sections

- Identify which valves controlled which fixtures

- Establish upstream and downstream relationships

- Reduce the leak zone to one specific side-yard section

Once the system was properly segmented, the pulse and ultrasonic tools became highly effective.

Leak Discovery & Resolution

After narrowing the search area:

- The PVC pipe run was traced

- Pulse response was identified

- The leak was located acoustically

The entire diagnostic process was completed within Pegasus’ standard 90-minute service window.

What could have become a multi-day, high-cost investigation was completed at the base service rate—solely because isolation valves were present.

Key Lessons & Industry Implications

1. Isolation Valves Are Critical

Properly placed isolation valves are the single most valuable feature in irrigation systems. They:

- Reduce diagnostic time

- Minimize excavation

- Provide clear testing boundaries

- Save homeowners thousands in future leak detection costs

Pegasus strongly recommends installing isolation valves during any irrigation repair or modification.

2. Plumbing Companies Are Not Leak Detection Specialists

Leak detection is not a plumbing task.

It requires:

- Acoustic training

- Interpretive experience

- Specialty equipment

- Structured isolation methodology

Each year, Pegasus is hired by plumbing companies after they fail to locate leaks they claimed they could handle.

Owning equipment does not equal competency.

3. The Need for Industry Regulation

This case highlights what happens without regulation:

- Anyone can claim to perform leak detection

- Customers receive misdiagnoses

- Unnecessary excavation occurs

- Costs escalate rapidly

- No standards exist for training or methodology

Regulation would protect consumers and establish professional accountability.

4. Professional Leak Detection Requires Method + Technology

This successful outcome was made possible by:

- Proper system isolation

- Experience with PVC irrigation systems

- Rhythmic pulse tracing equipment

- Ultrasonic detection tools

- A structured diagnostic process

This is not work that can be performed with basic plumbing gear or guesswork.

Conclusion: Expertise Prevents Escalation

Despite an unusually complex irrigation layout and the inherent limitations of PVC piping, Pegasus Leak Detection successfully isolated and located the leak within a standard service window.

Because the system contained isolation valves, a potentially expensive and prolonged investigation was avoided entirely.

This case reinforces:

- The critical value of isolation valves

- The necessity of trained leak detection specialists

- The risks posed by unregulated contractors

- The importance of proper methodology and specialized equipment

When leak detection is performed correctly, damage is minimized, costs are controlled, and homeowners are protected.